The most innovative system for oils yarns lubrication ever presented on the textile market.

The most innovative system for oils yarns lubrication ever presented on the textile market.  Born from a technological research and practical experimentation in the various stages of production in the textile industry, patented in various countries around the world, the device LUBRIFIL applied on the winding and doubling machines in addition to traditional waxing lubrication system, delivers exceptional results of performance on different types of yarns, from the synthetic yarn to natural yarn such as silk and wool, up to yarns such as flax and cotton either pure or in mixture with other fibres.

Born from a technological research and practical experimentation in the various stages of production in the textile industry, patented in various countries around the world, the device LUBRIFIL applied on the winding and doubling machines in addition to traditional waxing lubrication system, delivers exceptional results of performance on different types of yarns, from the synthetic yarn to natural yarn such as silk and wool, up to yarns such as flax and cotton either pure or in mixture with other fibres.

Advantages:

The advantages in productivity and quality that are visible by lubricating the yarn with the device LUBRIFIL are the following:

– Drastic decrease of the number of loop of threads that are formed during the step of doubling operation.

– Increase productivity in twisting and subsequent processing.

– Improvement of the smoothness of the yarn, eliminating broken yarn and decrease of yield machine, on the looms and on the knitting machines.

– Reduction of the electrostatic charge on the yarn making it ideal for silk, wool and synthetic yarns which in general tend to create static electricity charge.

– Reduction of hair free (fluff) and dust especially on staple yarns both synthetic and natural.

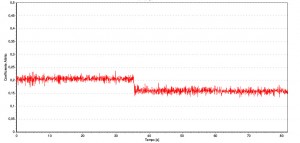

– Improvement of the intrinsic quality of the yarn both at the level of strength / elongation and at the level of defects like thick, think and neps .

– Drastic reduction in maintenance and cleaning of the device heads in the event of a change in item/colour.

Application principle:

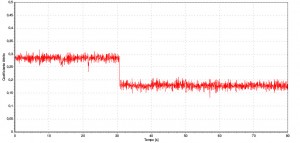

The lubrication of the yarn is obtained by exploiting the movement of yarn traverse during the winding operation. The yarn is in contact with a special material which could be in nylon, polyester, stainless steel, or porous sintered ceramic.

The yarn is self lubricated only when it is in motion with a dynamic oil distribution, more consistent and uniform as opposite to the tradition systems of waxing.

The device LUBRIFIL can be applied on the head of the winder machine with the waxing device (solid paraffin) as well. Using both systems of lubrication the results on the yarn will have an extremely low coefficient of friction. At any time it is possible to exclude the use of the device LUBRIFIL applying a protector on the head.

The oil supply is constant and controlled by a special feeding kit with the reservoir tank of 10 litres (model TOBY) that thanks to its self-leveling system of oiling guarantees a continuous and stable amount of oil dispensed. The power kit does not require electricity or compressed air.

LUBRIFIL can be used on all types of yarn without any limits in material and colour.

The installation on the machine is simple, fast and thanks to the experience of tens of thousands of winding units already in operation, the NUOVA RIMATES provides a kit of brackets ready for use.