LUBRY SMALL represents on the weaving market of one of the most important innovations of the last decade.

LUBRY SMALL represents on the weaving market of one of the most important innovations of the last decade.

The device was developed and patented in Italy by NUOVA RIMATES and it allows a drastic reduction of the friction coefficient of the weft yarn, increasing its smoothness and reducing the number of stops of the loom. This allows increasing the yield of the machine but especially reducing the defects on the fabric. Thanks to the special shape of the slot in ceramic positioned at the entrance of the device, the yarn, using the “ballon” of the yarn cone, flows, turning on itself, obtaining a perfect lubrication.

The yarn, on the device LUBRY SMALL slides on a specific material made of stainless steel (suggested for all natural and artificial yarns even in blends) or on a porous ceramic sintered material (recommended for synthetic yarns both continuous and textured).

Advantages:

The advantages in productivity and quality that are obtained by lubricating the yarn with the device LUBRY SMALL are the following:

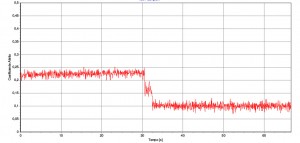

– Increased smoothness of the weft yarn with its friction reduction, ensuring a significant drop in breakage of the weft itself and its downtime of about -30% or -50% depending on the specific cases.

– Drastic reduction of the defects on the fabric and therefore the number of “second choice” caused by loom downtime.

– Reducing electrostatic charge of the yarn.

– Increase in the intrinsic tenacity of the yarn allowing an increase of the speed of the loom.

– Significant reduction in the formation of dust.

Application principle:

LUBRY SMALL comes with a convenient and simple tank oil supply incorporated in the device. Depending on the type of yarn and the amount of work expected there are two versions available: LUBRY SMALL 200 with a built-in tank of 200 cc lasting about 2-3 days of continuous work and LUBRY SMALL 500 with a built-in tank of 500 cc lasting about 5-6 days of continuous work.

A continuous use of the loom means continuous topping up the device with oil by the operator, in order to reduce the time dedicated to this operation, an additional tank of 250 cc can be applied directly on the device. With this option, the LUBRY SMALL 200, increase its capacity up to 450 cc while the model LUBRY SMALL 500, increased to 750 cc. Furthermore, there is an additional centralized kit with a capacity of 2,000 cc which allows constant and regular feeding of oil on the yarn without any intervention of operators. The kit centralized power is also oil self-leveling.

LUBRY SMALL can be installed on vertical, horizontal or even directly on the electronic yarn weft devices of the loom.